1. Inhloso yokuhlolwa kwesikhunta?

Iningi lokukhubazeka okubunjiwe kwenzeka ngesikhathi sokwenza ipulasitiki kanye nenqubo yokubumba, kodwa ngezinye izikhathi kuhlobene nomklamo wesikhunta ongenangqondo, kuhlanganise nenani lemigodi;umklamo wesistimu yomgijimi obandayo / oshisayo;uhlobo, isikhundla kanye nobukhulu besango lomjovo, kanye nesakhiwo sejiyomethri yomkhiqizo ngokwawo.

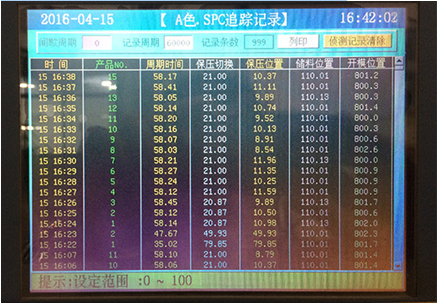

Ngaphezu kwalokho, ngesikhathi senqubo yokuhlola yangempela, ukuze kwenziwe ukuntuleka kokuklama isikhunta, abasebenzi bokuhlola bangase babeke ipharamitha engalungile, kodwa uhla lwangempela lwedatha yokukhiqiza ngobuningi oludingwa ikhasimende lulinganiselwe kakhulu, uma izilungiselelo zepharamitha nazo noma yikuphi ukuchezuka okuncane, ikhwalithi yokukhiqiza ngobuningi ingase iholele ngaphezu kwebanga elivumelekile lokubekezelela, izophumela ekukhiqizeni kwangempela kokwehla, izindleko zikhuphuke.

Inhloso yokuhlolwa kwesikhunta ukuthola imingcele yenqubo efanele kanye nomklamo wesikhunta.Ngale ndlela, ngisho nezinto ezibonakalayo, ipharamitha yomshini noma izici zemvelo zinokushintsha okuthile, isikhunta sisakwazi ukugcina uzinzile nokukhiqiza ngobuningi ngokungaphazanyiswa.

2. Izinyathelo zokuhlola isikhunta esizilandelayo.

Ukuqinisekisa ukuthi umphumela wesivivinyo sesikhunta ulungile, ithimba lethu lizothobela izinyathelo ezingezansi.

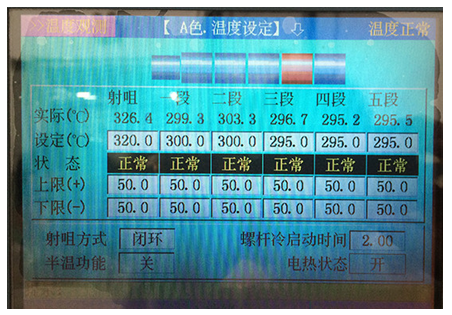

Isinyathelo1.Ukusetha izinga lokushisa lomshini womjovo "lombhobho we-nozzle".

Kufanele kuqashelwe ukuthi ukulungiselelwa kokuqala kwezinga lokushisa komgqomo kufanele kusekelwe esincomweni somphakeli wezinto ezibonakalayo.Bese ngokuya ngokwemibandela ethile yokukhiqiza yokulungisa kahle.

Ukwengeza, izinga lokushisa langempela lempahla encibilikayo emgqonyeni kufanele likalwe ngomtshina ukuze kuqinisekiswe ukuhambisana neskrini esibonisiwe.(Sibe nezimo ezimbili lapho amazinga okushisa amabili ahluka aze afike ku-30 ℃).

Isinyathelo sesi-2. Ukusetha izinga lokushisa lesikhunta.

Ngokufanayo, ukusetha kokuqala kwezinga lokushisa kwesikhunta kufanele futhi kusekelwe enanini elinconyiwe elinikezwe umphakeli wezinto ezibonakalayo.Ngakho-ke, ngaphambi kokuhlolwa okusemthethweni, izinga lokushisa le-cavities surface kufanele lilinganiswe futhi lirekhodwe.Ukulinganisa kufanele kwenziwe endaweni ehlukene ukuze kubonakale ukuthi izinga lokushisa liyalinganisela yini, bese ubhala imiphumela ehambisanayo yereferensi yokulandelela yokwenza isikhunta.

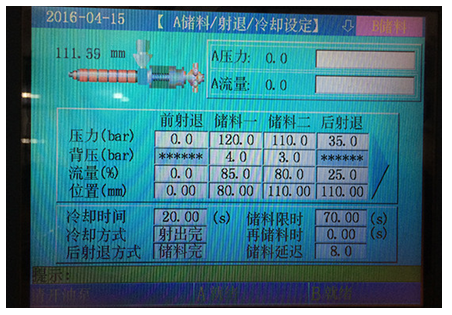

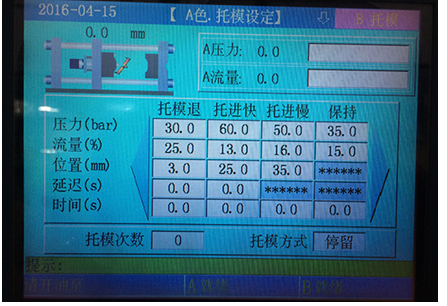

Isinyathelo sesi-3. Ukusetha amapharamitha.

Okufana nokwenza ipulasitiki, ingcindezi yomjovo, isivinini somjovo, isikhathi sokupholisa, nesivinini sesikulufu ngokuya ngesipiliyoni, bese usilungiselela ngendlela efanele.

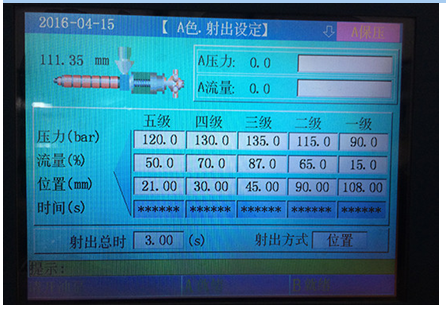

Isinyathelo sesi-4. Ukuthola indawo yokuguqula "yokubamba umjovo" ngesikhathi sokuhlolwa kokugcwalisa.

Iphuzu loguquko liyiphuzu lokushintsha ukusuka esiteji somjovo ukuya esigabeni sokubamba ingcindezi, okungaba indawo yesikulufu somjovo, isikhathi sokugcwalisa kanye nokucindezela kokugcwalisa.Lokhu kungenye yemingcele ebaluleke kakhulu futhi eyisisekelo enqubweni yokubumba umjovo.Esivivinyweni sangempela sokugcwalisa, amaphuzu alandelayo adinga ukulandelwa:

- Ingcindezi yokubamba kanye nesikhathi sokubamba phakathi nokuhlolwa ngokuvamile kumiswa kuqanda;

- Ngokuvamile, umkhiqizo ugcwaliswa ku-90% kuya ku-98%, kuye ngezimo ezithile zokuqina kodonga kanye nomklamo wesakhiwo sesikhunta;

- Njengoba isivinini somjovo sithinta ukuma kwendawo yokucindezela, kubalulekile ukuphinda uqinisekise indawo yokucindezela isikhathi ngasinye lapho ijubane lomjovo lishintshwa.

Phakathi nesiteji sokugcwalisa, singabona ukuthi izinto zigcwalisa kanjani isikhunta, ngaleyo ndlela sahlulele ukuthi yiziphi izikhundla ezilula ukuba nesicupho somoya.

Isinyathelo sesi-5. Thola umkhawulo wengcindezi yomjovo wangempela.

Ukusetha ingcindezi yomjovo esikrinini kuwumkhawulo wengcindezi yomjovo wangempela, ngakho-ke kufanele isethwe njalo ibe mkhulu kunomfutho wangempela.Uma iphansi kakhulu bese isondela noma idlulwe ingcindezi yomjovo wangempela, isivinini somjovo sangempela sizokwehla ngokuzenzakalelayo ngenxa yomkhawulo wamandla, okuzothinta isikhathi sokujova kanye nomjikelezo wokubumba.

Isinyathelo 6. Thola isivinini sokujova esingcono kakhulu.

Ijubane lomjovo okukhulunywe ngalo lapha yijubane lapho isikhathi sokugcwalisa sifushane ngangokunokwenzeka futhi ukucindezela kokugcwalisa kuncane ngangokunokwenzeka.Kule nqubo, amaphuzu alandelayo kufanele aqashelwe:

- Imikhiqizo eminingi engalungile ebusweni, ikakhulukazi eduze kwesango, ibangelwa isivinini somjovo.

- Umjovo wezigaba eziningi ungasetshenziswa kuphela lapho umjovo wesiteji esisodwa ungakwazi ukuhlangabezana nezidingo, ikakhulukazi ocwaningweni lwesikhunta.;

- Uma isimo sesikhunta sisihle, inani lokusetha ingcindezi lilungile, futhi isivinini somjovo sanele, khona ukukhubazeka kwe-flash yomkhiqizo akuhlobene ngokuqondile nesivinini somjovo.

Isinyathelo sesi-7. Lungiselela isikhathi sokubamba.

Isikhathi sokubamba siphinde sibizwe ngokuthi isikhathi esiqinile sesango lomjovo.Ngokuvamile, isikhathi singanqunywa ngokukala.okuholela esikhathini esihlukile sokubamba, futhi isikhathi sokubamba esiphezulu yisikhathi lapho isisindo sesikhunta sikhuliswa khona.

Isinyathelo 8. Ukulungiselela amanye amapharamitha.

Okufana nokubamba ingcindezi namandla okubamba.

Siyabonga kakhulu ngesikhathi sakho sokufunda lapha.ukwazi okwengeziwe mayelana nokuhlolwa kwesikhunta

Isikhathi sokuthumela: Jul-25-2020