Isikhunta sePlastiki iyithuluzi elihambisana nemishini yokubumba yepulasitiki embonini yokucubungula ipulasitiki ukunikeza imikhiqizo yepulasitiki ukucushwa okuphelele nosayizi oqondile. Ngokwezindlela ezihlukene zokubumba, ingahlukaniswa ngezinhlobo ezahlukene zokubunjwa.

1. Ukubumba kwe-polystyrene okunwetshiwe okuphezulu

Kuwuhlobo lwesikhunta esisebenzisa i-polystyrene enwebekayo (impahla yobuhlalu eyakhiwe nge-polystyrene kanye ne-ejenti ephuma amagwebu) izinto zokusetshenziswa ukwenza izinto zokupakisha zegwebu ezinobumo obufiswayo obuhlukahlukene.

Isimiso siwukuthi i-polystyrene enwebekayo ingashiswa esibunjeni, okuhlanganisa izinhlobo ezimbili zesikhunta esilula sokusebenza ngesandla kanye nesikhunta sepulasitiki se-hydraulic esiqonde ngegwebu, esisetshenziswa kakhulu ukukhiqiza imikhiqizo yokupakisha yemikhiqizo yezimboni. Izinto zokwenza isikhunta esinjalo ziyi-aluminium ephonsiwe, insimbi engagqwali, ithusi, njll.

2. Isikhunta sokucindezela

Kubandakanya ukubumba kokucindezelwa kanye nokubumba umjovo izinhlobo ezimbili zesikhunta sesakhiwo. Ziwuhlobo lwesikhunta esisetshenziselwa ikakhulukazi ukubumba amapulasitiki e-thermosetting, futhi imishini yawo ehambisanayo ingumshini wokubumba umshini wokunyathelisa.

Indlela yokubumba yokucindezela Ngokwezici zepulasitiki, isikhunta sishiselwa ekushiseni okubumbile (ngokuvamile i-103 ° 108 °), bese i-powder yokubumba elinganiselwe ifakwa emgodini wokubumba kanye negumbi lokudla, isikhunta sivaliwe, futhi ipulasitiki iyashiswa ngaphansi kokushisa okuphezulu nokucindezela okukhulu. Thambisa ukugeleza kwe-viscous, uqinise futhi ulolonge ngemva kwesikhathi esithile, futhi ube yisimo somkhiqizo oyifunayo.

Umehluko phakathi kokubumba umjovo kanye nokubunjwa kokucindezela ukuthi alikho igumbi lokuphakela elihlukile. Isikhunta sivaliwe ngaphambi kokubunjwa, futhi ipulasitiki ishisa ekamelweni lokudla futhi iba yisimo sokugeleza kwe-viscous. Ngaphansi kwesenzo sokucindezela, iyalungiswa futhi ifakwe emgodini wesikhunta ukuze uqine futhi wenze.

Isikhunta sokucindezela ikakhulukazi sakhiwe ngomgodi, umgodi wokuphakela, indlela eqondisayo, izingxenye ezikhiphayo, isistimu yokushisisa, njll. Isikhunta sokujova sisetshenziswa kakhulu ekupakisheni izingxenye zikagesi. Izinto ezisetshenziswa ekwenziweni kwezibunjwa zokucindezelwa ziyafana ngokuyisisekelo nezibunjwa zokujova.

3. Isikhunta sokujova

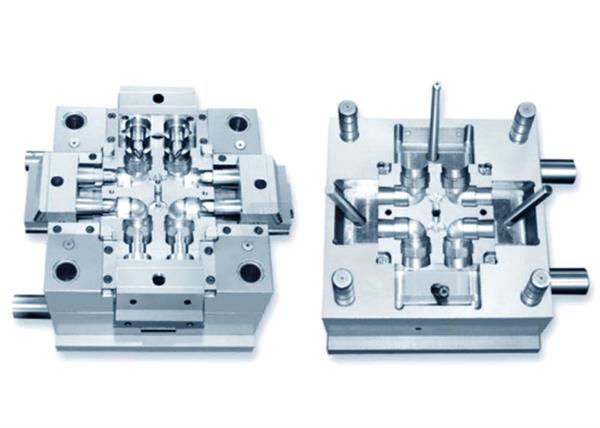

Ngokuyinhloko isikhunta sokubumba esisetshenziswa kakhulu ekukhiqizeni izingxenye ze-thermoplastic. Imishini yokucubungula ehambisana nesikhunta sokujova ingumshini wokubumba umjovo. Ipulasitiki iqala ukushisisa futhi incibilike emgqonyeni wokushisa phansi komshini wokubumba umjovo. Ngaphansi kokucindezela kwepulaki, ingena emgodini wesikhunta ngokusebenzisa i-nozzle yomshini wokubumba umjovo kanye nesistimu yokuthulula yesikhunta, futhi ipulasitiki ipholile futhi iqiniswe ukuze yakheke, futhi umkhiqizo utholakala ngokudilizwa.

Isakhiwo sawo ngokuvamile sakhiwe izingxenye ezakha, uhlelo lokuthulula, izingxenye eziqondisayo, indlela yokuphuma, uhlelo lokulawula izinga lokushisa, uhlelo lokukhipha umoya, izingxenye ezisekelayo nezinye izingxenye, futhi lenziwe ngensimbi yokubunjwa kwepulasitiki. Inqubo yokubumba umjovo ngokuvamile ifaneleka kuphela ukukhiqizwa kwemikhiqizo ye-thermoplastic. Imikhiqizo yepulasitiki ekhiqizwa inqubo yokubumba umjovo ibanzi kakhulu. Kusukela ezidingweni zansuku zonke kuya ezintweni ezihlukahlukene eziyinkimbinkimbi zikagesi nezingxenye zezimoto, zonke zakhiwe ngesikhunta sokujova. Enye yezindlela ezisetshenziswa kakhulu zokucubungula ekukhiqizeni imikhiqizo yepulasitiki.

4. Vuthela isikhunta

Isikhunta esisetshenziselwa ukwenza imikhiqizo engenalutho yesitsha sepulasitiki (njengamabhodlela eziphuzo, imikhiqizo yansuku zonke yamakhemikhali nezinye iziqukathi zokupakisha). Indlela yokubumba igalelo ikakhulukazi ihlanganisa ukubunjwa kwe-extrusion blow kanye nokubunjwa komjovo ngokuya ngesimiso senqubo. Isimiso ngokuyinhloko sihlanganisa ukubunjwa kokushaywa kwe-extrusion, ukubunjwa kokushaywa komjovo, ukubunjwa kokushaywa komjovo (okuvame ukwaziwa ngokuthi i-injection stretch blow), ukubunjwa kwe-multi-layer blow, ukubunjwa kweshidi, njll. Izinto ezisetshenziswayo ezihambisana nokubunjwa kokushaywa kwemikhiqizo engenalutho ngokuvamile kubizwa ngokuthi ipulasitiki. umshini wokubumba wokushaya, futhi ukubunjwa kwe- blow kulungele kuphela ukukhiqizwa kwemikhiqizo ye-thermoplastic. Isakhiwo sesikhunta sokushaywa silula, futhi izinto ezisetshenziswayo ngokuvamile zenziwe ngekhabhoni.

5. Extrusion die

Uhlobo lwesikhunta esisetshenziselwa ukukhiqiza imikhiqizo yepulasitiki emile, eyaziwa nangokuthi i-extrusion molding head, isetshenziswa kabanzi ekucubunguleni amapayipi, imigoqo, ama-monofilaments, amapuleti, amafilimu, izintambo nezintambo, izinto ezifakwe iphrofayili, njll.

Imishini yokukhiqiza ehambisanayo iyi-extruder yepulasitiki. Isimiso siwukuthi ipulasitiki eqinile iyancibilika futhi yenziwe ipulasitiki ngaphansi kwezimo zokushisisa kanye nokuzungeza isikulufu se-extruder, futhi yenziwe ibe yisigaba esiphambanayo esifanayo nokuma kwe-die ngokusebenzisa i-die of shape ethize. Imikhiqizo yepulasitiki eqhubekayo. Izinto zayo zokukhiqiza ziyinsimbi ye-carbon structural, amathuluzi e-alloy, njll., kanti amanye ama-extrusion dies nawo ahunyushwe ngezinto ezingagugi njengedayimane ezingxenyeni ezidinga ukumelana nokuguga.

Inqubo yokukhishwa ngokuvamile ifaneleka kuphela ukukhiqizwa kwemikhiqizo ye-thermoplastic, ehluke kakhulu ekubunjweni komjovo kanye nokubunjwa kokucindezela esakhiweni.

6. Isikhunta sebhamuza

Isikhunta esisebenzisa amapuleti epulasitiki namashidi njengezisetshenziswa zokusetshenziswa ukwakha imikhiqizo yepulasitiki elula. Endabeni yokuthambisa, ikhubazekile futhi ixhunywe emgodini wesikhunta ukuze kutholwe umkhiqizo obunjiwe owufunayo, osetshenziswa kakhulu ekukhiqizeni ezinye izidingo zansuku zonke, ukudla kanye nemikhiqizo yokupakisha yamathoyizi.

Isikhathi sokuthumela: Feb-12-2022